Tech

We have taken a radically different approach in the development of our patented Proton Exchange Membrane (PEM) electrolyzer technology: the HEVO. The HEVO is a miniaturized electrolyzer that sits at the core of each of our products and unlocks cost-competitive green hydrogen solutions at any scale and for any application. By contrast, we have arrived at a solution that is unlike any other in the market today, the HEVO.

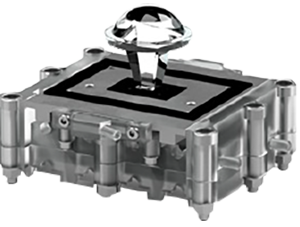

We designed the HEVO from the inside-out, building on a completely new approach to membrane electrode assembly (MEA) and electrochemical cell design which allows for unprecedented modularity, cost reduction and process simplification. Each of our MEAs is the size of a business card, compared to the membranes used in a traditional PEM electrolyzer which are the size of a sheet of printer paper, which enables near immediate response times to rapid fluctuations in power supply.

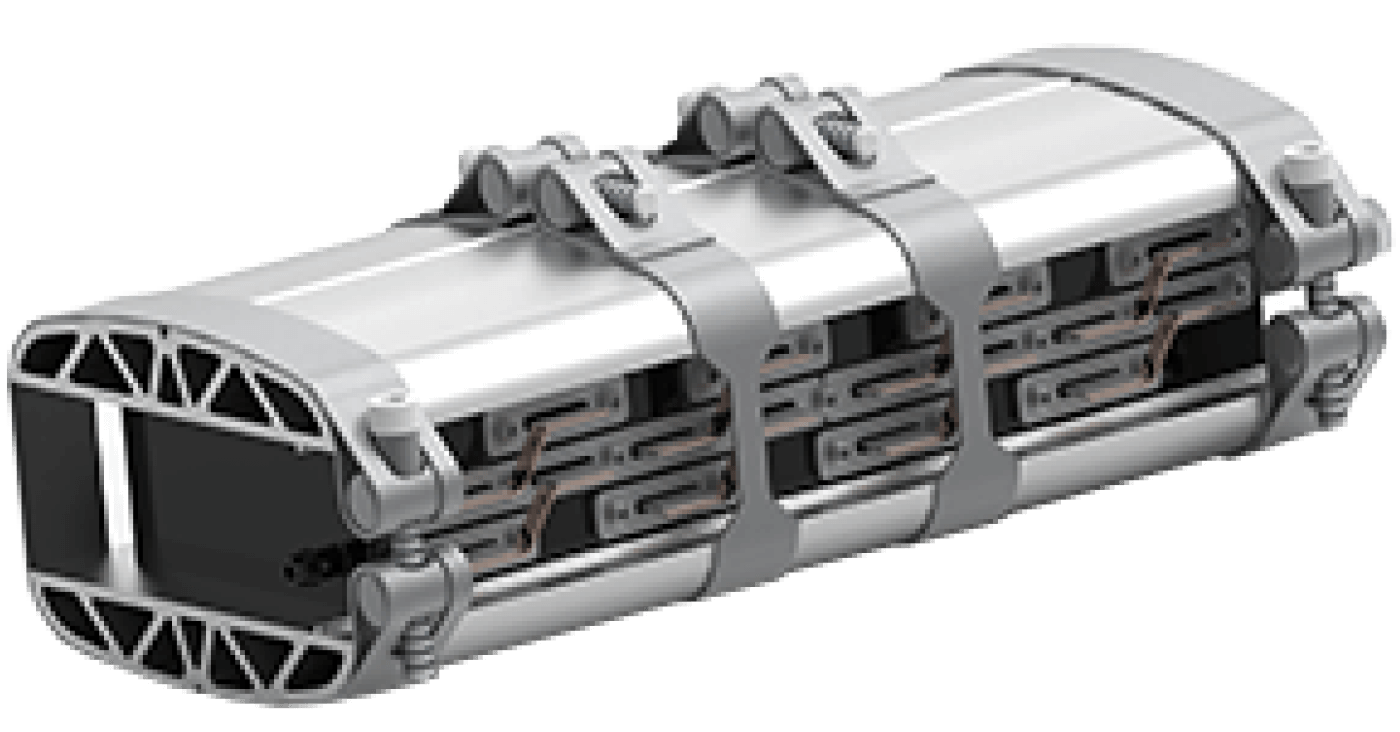

The revolutionary HEVO is at the heart of our entire product suite. The HEVO can be grouped in different ways to best suit the client needs, the conditions of where it will be installed and the total size of the system. Fusion Fuel has created the following offerings that can suit most client needs, these are the HEVO-Chain, with its Series NC and Series C version, as well as the HEVO-Solar.

of system and ease of manufacturing

HEVO Mini-PEM Architecture

power equipment

long-term performance

increased uptime

response time

of production

modular deployment